The removal of material from metal is called Machining, and the process usually happens in a machine shop that has special equipment. Parts of lathe machine Headstock: The headstock is fixed on the machine and it consists of many pulleys, lever, spindle, chuck, and gear box.

Milling Operations in The Lathe Workshop Practice Series 05 by Tubal Cain. The lathe and a drilling machine can be used for milling work operation as basic machines. Lath is a universal machine can be adapted for almost any function its most valuable use is for milling work is practical experience is described in the book.

Contents in Milling Operations in The Lathe machine

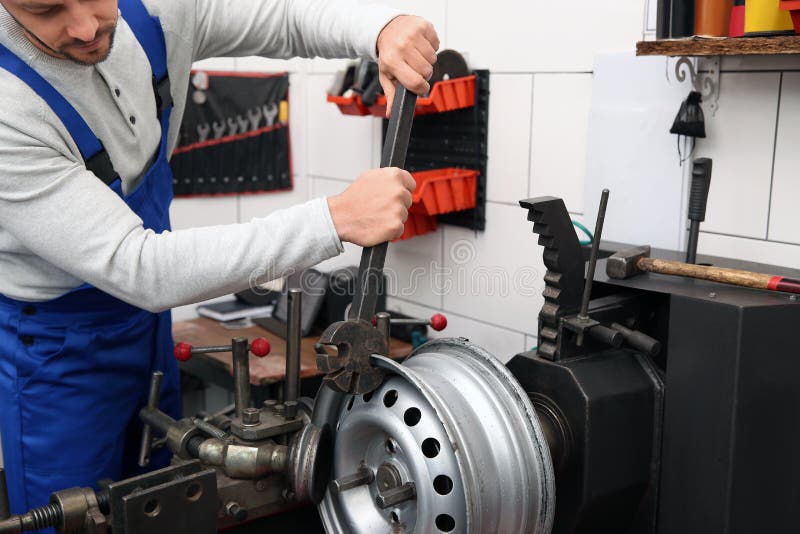

The rim repair lathe machine is a lathe specially designed for repairing the surface of the wheels. It can detect the surface curve of alloy wheel and generate the machining program automatically, and using the diamond cutter to repair the wheel end-face. After detection, the program will be automatically generated, it is very simple to. Absolutely check the lathes for true (levelling is the easiest way, as M.B. If the problem is wear, it's still quite easy to 'tap in' a fairly true diameter - if you don't have good DRO, you don't use the dials to do that, you use a dial indicator set to register on the cross slide or the tool/toolpost, etc.

Introduction

The Lathe as a Milling Machine

Milling Cutters

Tooth Geometry, Speeds and Feeds and Cutter Holding

Work holding devices

Milling Attachments

Indexing and Dividing

Procedures and Case Studies

Combined Operations and Complex Milling

Lathe Machine ..introductionthe Mechanic

Care of cutters